The Tom Love Innovation Hub prototyping services launched in 2020 to support entrepreneurs, researchers, and help fight the COVID-19 pandemic. In 2021, the Innovation Hub will expand their prototyping services to include two new offerings, a waterjet cutting machine and CNC mill.

The waterjet cutting machine, funded through an Economic Development Administration Cares Act grant focused on aerospace and defense venture support, provides precision cutting of virtually any material, including, for example, carbon fiber.

Innovation Hub labs director Brandt Smith said, “OU has so many people who work in aerospace and drone research, the Radar Innovation Lab, the Weather Center and others who use a lot of carbon fiber. Without a waterjet, cutting carbon fiber is a time, quality, and safety nightmare. If you’re using scissors, it takes forever and is rough. If you machine it, it creates a lot of particulate dust that is very dangerous to breathe. This waterjet makes working with carbon fiber safer with high quality, precise results.”

Tom Wavering, Innovation Hub executive director, said the grant also supports two goals beyond the machine’s procurement.

“The goals of the grant are two-fold, workforce development – how to train more engineers to meet the needs of our warfighters in the military, and how do we promote and grow more aerospace and defense businesses in Oklahoma to leverage this workforce we are creating,” Wavering said. “As we’re able to scale our research support and prototyping, we’re creating more real-world experiences for students, as well as supporting research and entrepreneurial endeavors.”

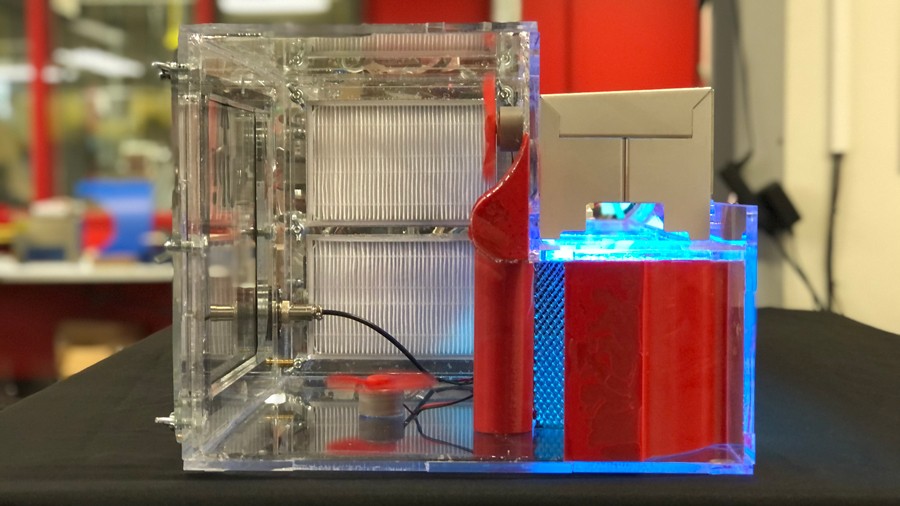

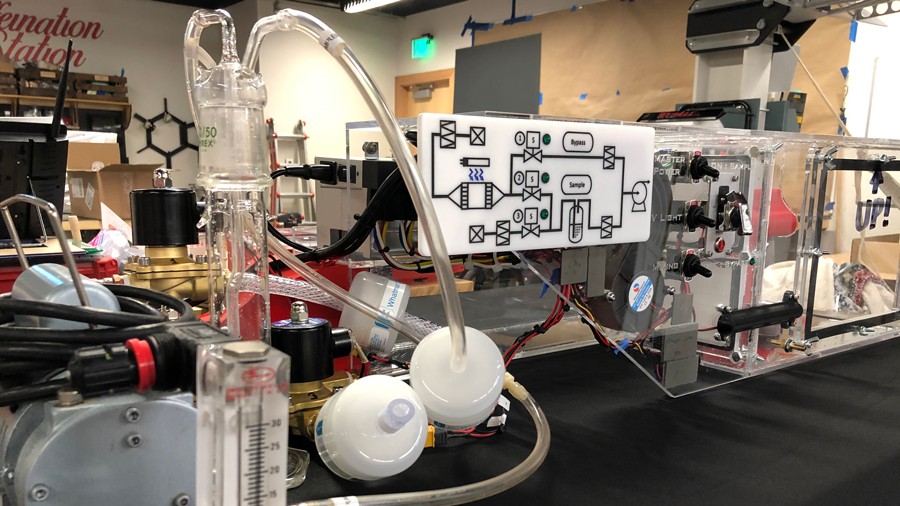

A chamber for testing ultraviolet light wavelengths in the UVC range for disinfection of air at velocity, made for Dr. Evan Floyd with the Hudson College of Public Health. The system involves an agitation chamber, a laminar flow chamber with exposure to the UVC light, and then an automated testing and purging system.

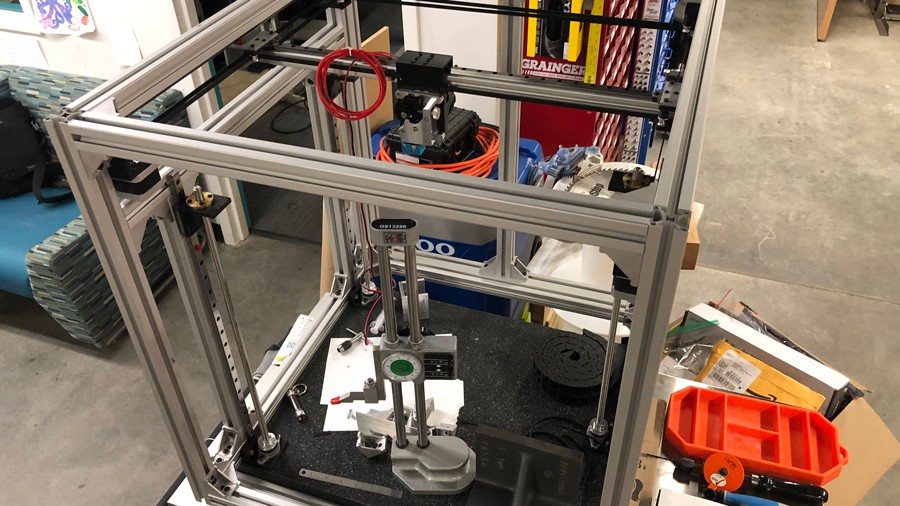

The second new capability, while not unique on campus, is a CNC milling machine that enables precision milling of metals and plastics.

“Other CNC machines on campus are dedicated to a specific department or unit, while ours will be available to anyone and everyone,” Smith said.

Wavering said among the unique features of the Innovation Hub’s support for the research apparatus, campus and broader community is their speed and affordability, while also providing unique experiential opportunities for students.

“We want to make sure that researchers and inventors out there looking for help, looking for support, know that there are resources they that already exist on campus,” Wavering said. “We have an amazing group of students and full-time staff, like Brandt and Francisco Robles (prototyping manager), who are doing this every day who are highly skilled and highly trained.”

Wavering added, “Our prototyping services are designed to accelerate research and product development. Since we already have the equipment and trained experts in house, we can be very responsive.”

These new services add to the lab’s existing prototyping and design services which include:

Researchers interested in learning more or scheduling an appointment to discuss prototyping or design are encouraged to contact Smith at brandt@ou.edu.