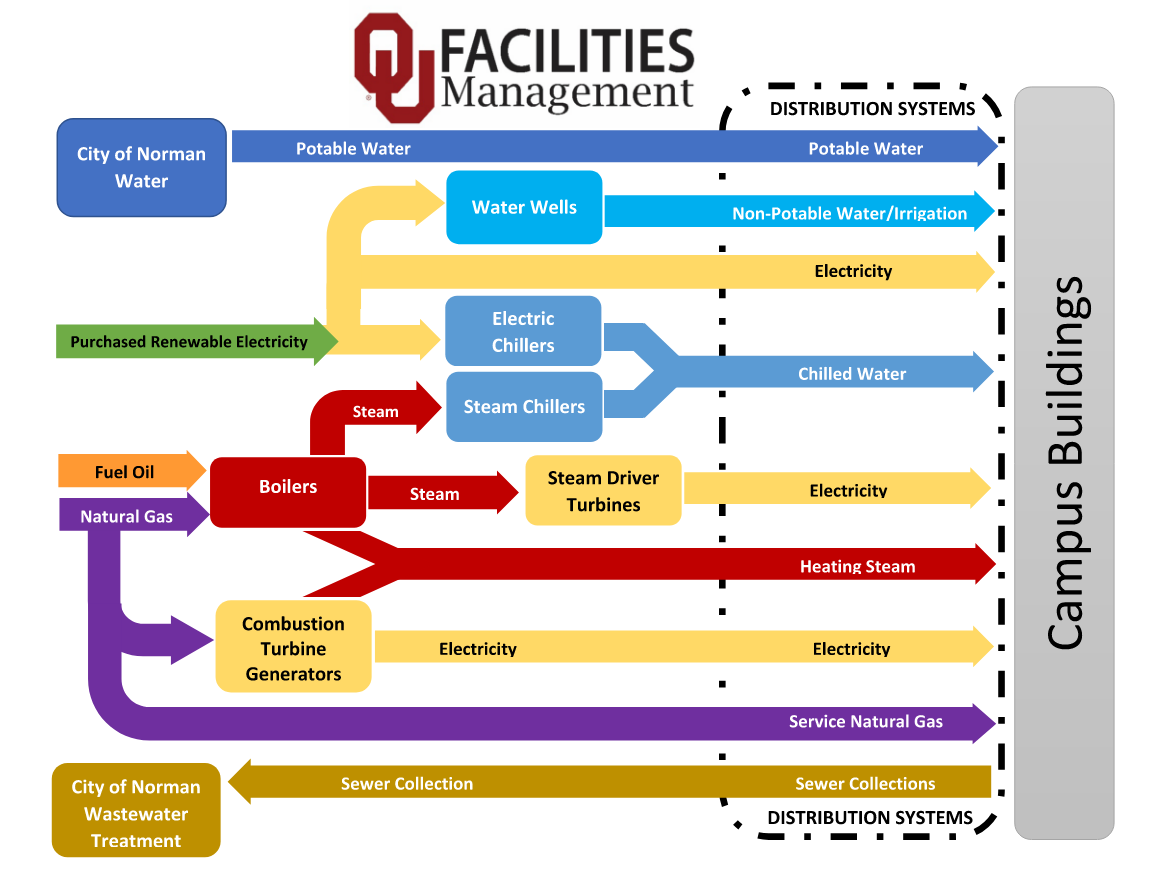

Utilities on the Norman Campus support over 28,000 students in approximately 300 buildings on 3,000 acres. The utilities are steam, chilled water, electricity, natural gas, water, wastewater, compressed air, deionized water, and tunnel structures. Services include the following:

Operate and maintain equipment and distribution systems.

Capital project management and support of OU growth projects.

Monthly meter reading (approximately 750 meters) for customer usage and billing.

Locating and flagging underground utilities for dig requests.

Ensuring compliance with Local, state, and federal regulatory requirements.

A snapshot of each commodity and the lifecycle is below. For detailed information about each commodity, click the specific commodity under the Mission Statement.