Machine Learning has tremendous potential to revolutionize the speed at which large data sets are processed in the petroleum industry; however, caution must be exercised.

The petroleum industry generates tremendous amounts of data, often faster than it can process it, and even in cases where the data is being utilized, it is often not to its full potential. The capacity at which humans can process the data with direct programming of computers is limited. Machine Learning (ML), a subset of Artificial Intelligence (AI) stands primed to offload a lot of the work.

Imaging techniques such as scanning electron microscopy (SEM) have proven to be valuable tools to oil and gas exploration and production especially in unconventional reservoirs such as shale. SEM imaging is qualitatively indispensable in understanding microstructure and porosity. Quantitative measurements of porosity, pore connectivity, and pore size distributions are regularly made but lack statistical significance due to the small number of images often analyzed. To obtain meaningful statistics, a large number of SEM images would need to be analyzed which is time-consuming and labor-intensive. The bottle-neck here is usually not a result of image acquisition time, but rather in the rapid and accurate analysis of the images. In addition, many current methods of feature extraction fall short of the robustness needed for accuracy required for subsequent analysis.

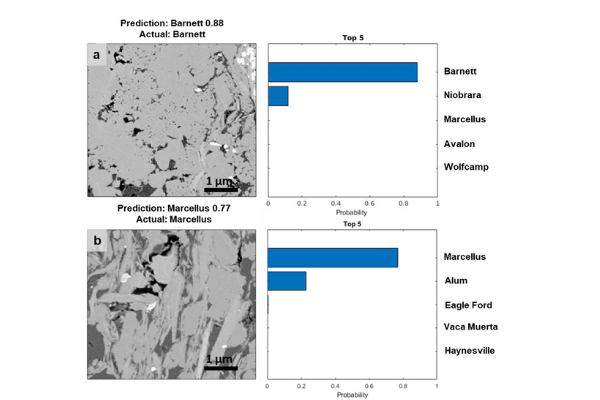

We aim to accelerate and automate the feature extraction process, by training a computer to recognize microstructural features. We have started with simple tasks and asked the question: Is microstructure unique to a given shale and can the machine identify the play from which this image came based purely on microstructure? To a degree, this is something that the human brain can rapidly accomplish, but is difficult with current computer-based feature extraction methods. One can look at the SEM images of Barnett shale and Marcellus shale shown in Figure 1 and with appropriate training, be fairly confident which one each image belongs to based off of visual inspection of the microstructure. We utilized our unique database of over 27,000 SEM images from 18 different shale formations to train a computer to do just this. The computer currently is able to accurately identify the shale formation from only the SEM image of its microstructure, 91% of the time. The network assigns a probability as to what shale formation the image belongs to. Shales with similar microstructural features often have higher probabilities. When the computer did not predict the correct shale from the image, many of the incorrected assignments were due to two or more plays having similar microstructures. Shales are known to have significant heterogeneity within a play, which will need to be explored to establish the robustness of the results.

The problem new technologies often face is that they get over-sold, fail to meet expectations, and are discarded as unreliable. Machine learning is no different. While machine learning shows significant promise in SEM image analysis, caution needs to be exercised. The results coming out of machine learning experiments need to be validated and scrutinized. The computer may find trends in data that are meaningless or worse, misleading. We are encouraged that our preliminary work shows a computer can be trained to identify microstructural features in shale SEM images and determine which shales are similar in microstructure. We are using this work to extend that to feature extraction, i.e. porosity, organic and inorganic porosity, cracks and minerals; however, we continue to provide validation and checks on the results as well as improved training through better data sets.