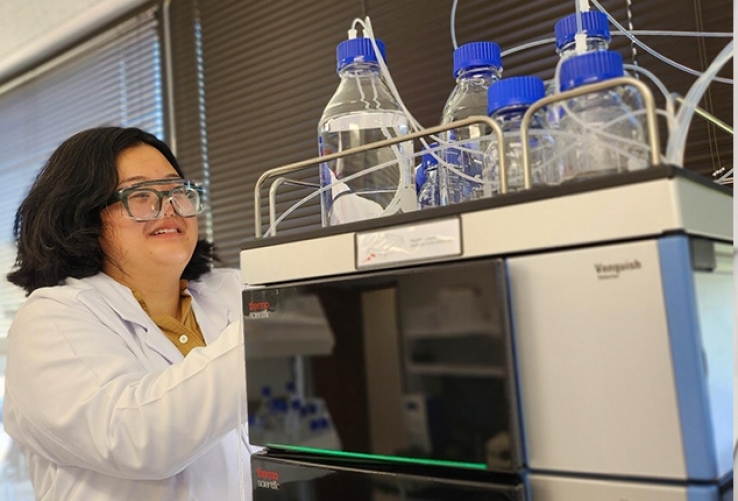

The OU Bioprocessing Core Facility (OU BPCF) provides students and industry professionals with a state-of-the-art training in biomanufacturing. Committed to developing a skilled and career ready workforce, our programs blend theoretical knowledge with hands-on experience, equipping undergraduate and graduate students, as well as industry professionals, with the practical skills and technical expertise needed to thrive in the biotech industry.

Graduate Online Certificate Program - Launching Fall 2026

jennifer.r.jones-1@ou.edu

405-325-5814

Bioprocessing is a manufacturing process for products such as proteins, enzymes, vaccines and monoclonal antibodies produced by biological systems such as cells or enzymes.

The bioprocessing workflow includes several steps listed below:

The biotech industry is rapidly growing, with biologic drugs now making up nearly half of the pharmaceutical market.

Bioprocessing is inherently multidisciplinary, requiring collaboration across cell biology, biochemistry, engineering, and quality assurance. It drives the production of biopharmaceuticals and other bio-based products with wide-ranging applications in healthcare, agriculture, food, and environmental industries.

With an annual growth rate of nearly 14%, biotechnology has become one of the largest, most diverse, and fastest-growing sectors—offering engineers lucrative, plentiful, and expanding career opportunities.

The OU Bioprocessing Certificate is open to both undergraduate and graduate students.

Undergraduate Certificate – A 15-hour program with three required core courses (9 hours) and two electives (6 hours) selected from the program curriculum.

Graduate Certificate – A 12-hour program with three required core courses (9 hours) and one elective (3 hours) selected from the offered electives within the program curriculum.

The 9-hour core curriculum provides students with a comprehensive foundation in bioprocessing, covering both technical and theoretical aspects.

Core areas include:

Gene and Cellular Engineering (CHE/BME-5423/4423): State-of-the-art technologies for manipulating genes, genomes, and cellular pathways to engineer human stem cells and microbes for health, environmental, and biomanufacturing applications.

Bioprocessing Fundamentals (CHE/BME-5243/4243): Key principles of biochemical engineering, biochemistry, and microbiology applied to current reaction and separation processes.

Biomanufacturing Workflow (CHE558/4583): Upstream and downstream bioprocessing of biological products, emphasizing design and operation of industrial practices at the OU Bioprocessing Core Facility.

Course Number | Course Title |

|---|---|

| CH E/BME 5423/4423 | Genetic Engineering and Biotechnology |

| CH E/BME 5373/4373 * | Tissue Engineering * |

| CH E/BME 5243/4243 | Biochemical Engineering |

| CH E 5583/4583 | Advanced Techniques in Biomanufacturing |

* Tissue Engineering (CH E/BME 5373/4373) is an and/or option for Genetic Engineering and Biotechnology (CH E/BME 5423/4423).

While the common core serves as the foundation, the selection from the electives allows for a broader understanding of bioprocessing in a variety of course options.

Undergraduate students must complete two elective courses (6-hours) from the electives offered within this program curriculum.

Graduate students must complete one elective course (3-hours) from the offered electives within this program curriculum.

Graduate students apply for the Graduate Bioprocessing Certificate Program below.

Once complete, email your application to Jennifer Jones at Jennifer.R.Jones-1@ou.edu

Complete the Graduate Application (PDF)

Undergraduate Students apply for the Undergraduate Bioprocessing Certificate Program below .

Once complete email your application to Mikaela Sullivan at Mikaela.K.Johansson-1@ou.edu

Complete the Undergraduate Application (PDF)

Graduate Students Only

In your final semester of course work please select the link below and complete the Graduate Certificate Program Report (GCPR):

Graduate Certificate Program Report

Once complete, please email your GCPR to Dr. Vassilios Sikavitsas at vis@ou.edu.

Questions?

Graduate Bioprocessing Certificate Program

Jennifer Jones

Jennifer.R.Jones-1@ou.edu

Undergraduate Bioprocessing Certificate Program

Mikaela Sullivan

Mikaela.K.Johansson-1@ou.edu

Open to undergraduate and graduate students in STEM fields, academic researchers, and professionals in the biotech industry, our hands-on training programs deliver career-ready skills and translational experience. Participants engage in a blend of theoretical and practicial application at the OU BPCF, a state-of-the-art facility specializing in bioprocessing and biomanufacturing.

April 27th - April 29th, 2026

9am - 5pm CST

OU Affilates and Students - $1,000.00

Non-OU Affilates - $2,000.00

Registration Link:

https://oupacsrcc.ungerboeck.net/prod/emc00/register.aspx?aat=4e67654b696362676d363675496c6a454f756c4b5a6f522b7a56505977362b6b44705a4f354e696f43746f3d

May 7th - May 8th, 2026

9am - 5pm CST

OU Affilates and Students - $600.00

Non-OU Affilates - $1,000.00

Registration Link:

https://oupacsrcc.ungerboeck.net/prod/emc00/register.aspx?aat=4a7969524c50476f394d58473667497846437944686e54303242734f4f725856484e6b6c664f796e4d50773d

May 5th, 2026

9am - 5pm CST

OU Affilates and Students - $500.00

Non-OU Affilates - $1,000.00

Registration Link:

https://oupacsrcc.ungerboeck.net/prod/emc00/register.aspx?aat=754c484e355a69495752426b4b727964445a6b6c6c32396a436b72416b4e55357754764a5a7968787954773d

May 1st, 2026

9am - 5pm CST

OU Affilates and Students - $500.00

Non-OU Affilates - $1,000.00

Registration Link:

https://oupacsrcc.ungerboeck.net/prod/emc00/register.aspx?aat=355243654b634d722b706855336b396e384c612f58307838416a364a744e495377707331616957653471553d

This hands-on workshop introduces participants to the Ambr® 250 High Throughput System, a cutting-edge parallel bioreactor system used in automated biomanufacturing. Learn how to set up and operate the system, navigate its software interface, and design bioreactor experiments. The training also includes a seminar led by industry professionals and a guided tour of a commercial biomanufacturing facility, offering real-world insights into automation in bioprocessing.

Key take aways include:

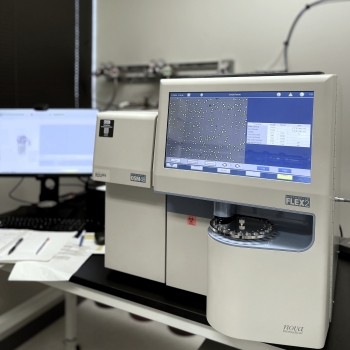

This workshop focuses on the BioProfile®FLEX2, an essential tool for in-process control (IPC) and monitoring of cell culture parameters during upstream production of biologics in the biomanufacturing industry. Participants will gain practical experience with the hardware and software, learning how to run, analyze, and validate samples for in-process control. This training equips attendees with foundational skills in biomanufacturing analytics, preparing them to confidently support quality and efficiency in biologics production.

Key take aways include:

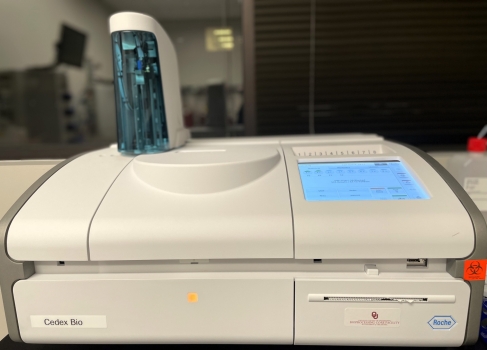

This workshop equips participants with the skills to confidently operate Cedex® Bio Analyzer, an essential analytical instrument for metabolite and product quantification in the biomanufacturing industry during upstream production of therapeutics and bio-based products. Learners will gain hands-on experience with system setup, software operation, and sample validation. The training emphasizes analytical techniques for measuring protein and monoclonal antibody concentrations, as well as key metabolites, supporting quality control in both mammalian cell culture and microbial fermentation workflows. Completion of this workshop prepares participants to confidently apply these tools in real-world bioprocessing environments.

Key take aways include:

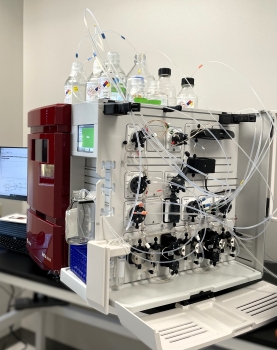

Learn the principles and hands-on operation of column chromatography using the ÄKTA avant™ 150 system. This workshop combines lectures, demonstrations, and practical lab sessions to give participants both conceptual understanding and real-world experience in protein purification. Explore various chromatography modes including affinity, ion exchange, and size-exclusion, while gaining proficiency in UNICORN software for method design, monitoring, and data analysis.

Key take aways include:

This state-of-the-art biotechnical facility, located in Oklahoma City’s Innovation District, is led by Dr. Farid Talebnia Rowshan.

This state-of-the-art biotechnical facility, located in Oklahoma City’s Innovation District, is led by Dr. Farid Talebnia Rowshan.

The facility includes nine laboratories equipped with industry-leading technology used across the biopharmaceutical sector. These state-of-the-art systems support both upstream and downstream bioprocessing, scalable up to the pilot level.